Since 1974, the name Solupharm represents high-quality and responsible contract manufacturing of sterile preparations in glass ampoules and glass vials. Our new building in Melsungen, in the centre of Germany, is one of the most modern production facilities in Europe.

Since 1974, the name Solupharm represents high-quality and responsible contract manufacturing of sterile preparations in glass ampoules and glass vials. Our new building in Melsungen, in the centre of Germany, is one of the most modern production facilities in Europe.

Many years of experience, efficiency and professionalism make our family-owned company a strong and reliable partner for national and international customers.

- Industry experience since 1974

- State-of-the-art production technology

- Expertise at the highest level

Your Partner for Parenterals. Parenterals!

Solupharm at a Glance

Vision Human

Aware of our Responsibility.

The management of Solupharm Pharmazeutische Erzeugnisse GmbH:

Dr Jürgen Gäb as Pharmaceutical Director (left),

Thomas Zimmermann as Commercial Director (centre) and

Managing Director Friedemann Seitz (right).

Our Mission Statement

Since 1974, Solupharm is a successful contract manufacturer of Parenterals. We manufacture sterile medicinal products in glass ampoules and glass vials at our modern site in Melsungen in the centre of Germany.

Our History

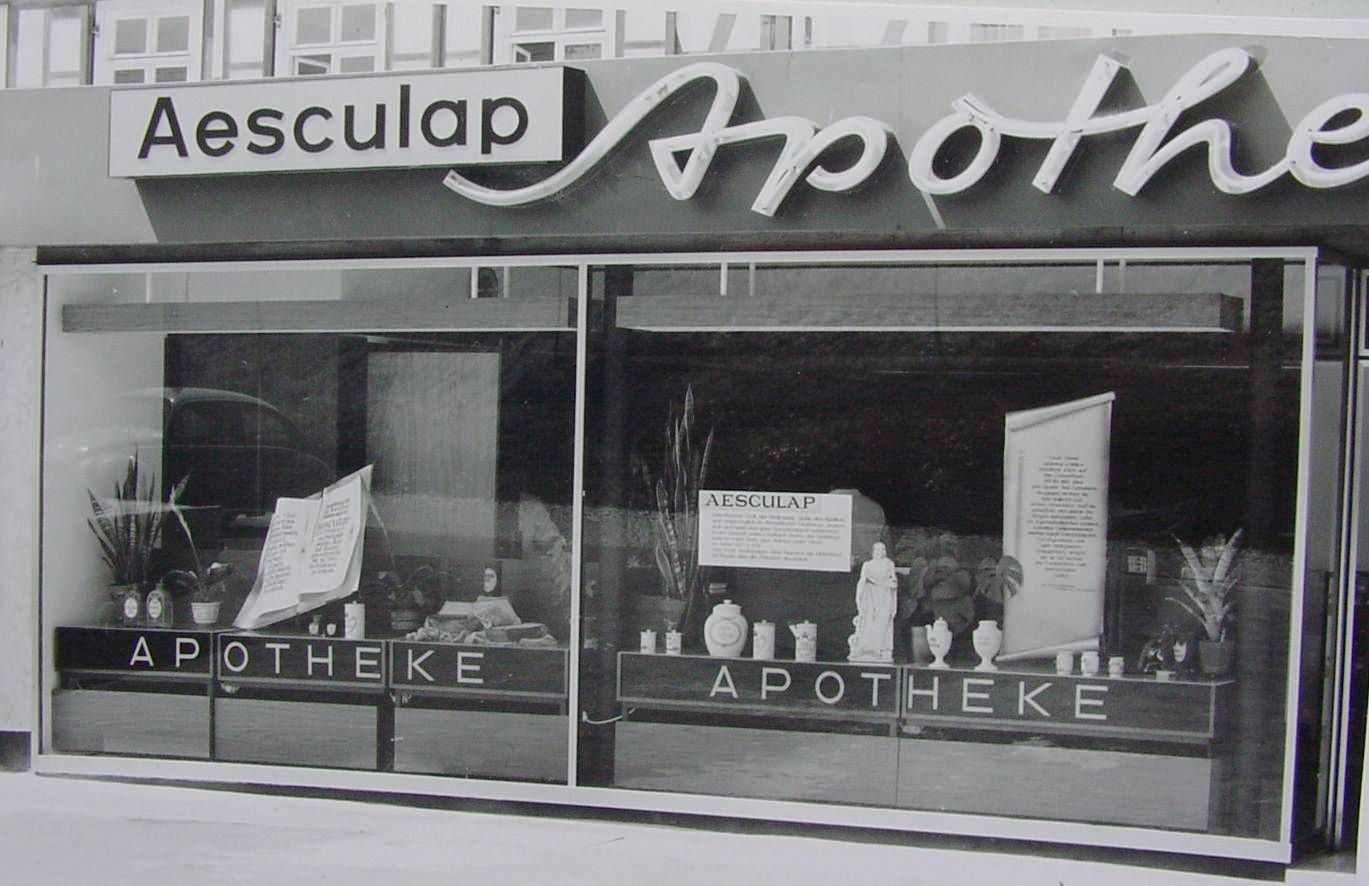

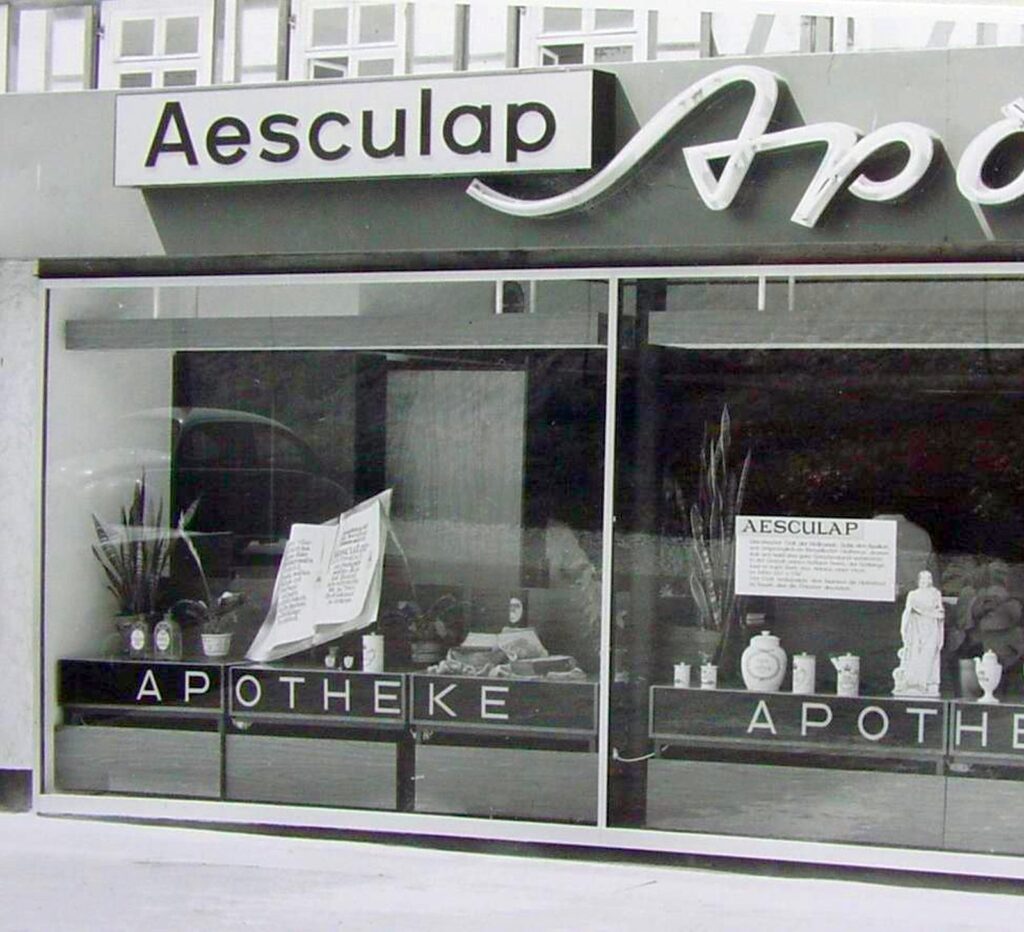

Solupharm emerged from the Aesculap pharmacy in Melsungen, which is still in family hands today. At the end of the 1960s, the Aesculap pharmacy was already producing sterile medicines for a well-known hospital supplier in Melsungen.

Solupharm as your Employer

Your career starts here and now!

For us, VISION PEOPLE also means that our employees take centre stage. We at Solupharm are a family-run company – familiar, appreciative, flexible and open.

A modern company with clear structures that still leave room for flat hierarchies. At Solupharm, the doors are open – whether for dialogue, criticism, questions or suggestions.

„At the end of it, there is always a human life”

As one of the leading companies in contract manufacturing for parenterals, we bear a lot of responsibility, master challenges and always work dynamically as a team. Become a part of it!

Start your Career now!

The Short Line to Solupharm

Question, suggestion, application, order? No matter what your request is, don’t search long for your contact person and simply write to us! Quick, uncomplicated and direct. We will get back to you as soon as possible!